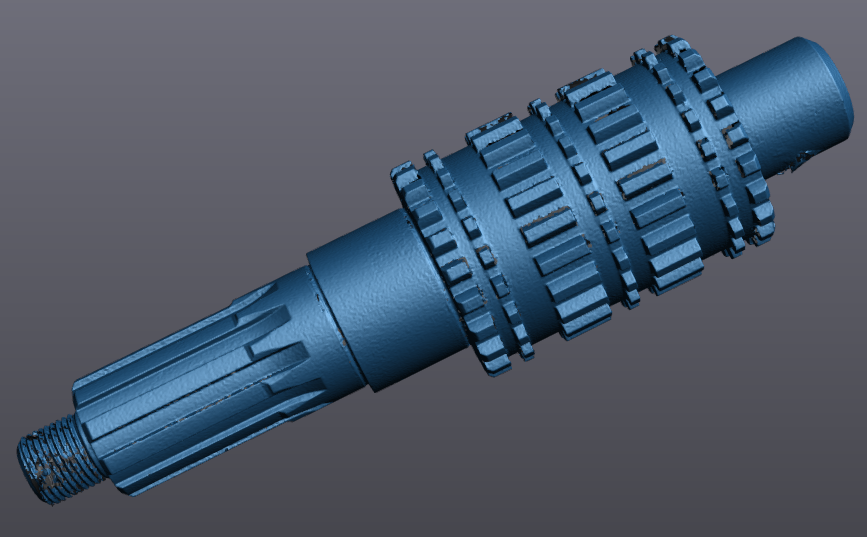

SHAFT OPERATING ON A CARDBOARD WINDING MACHINE

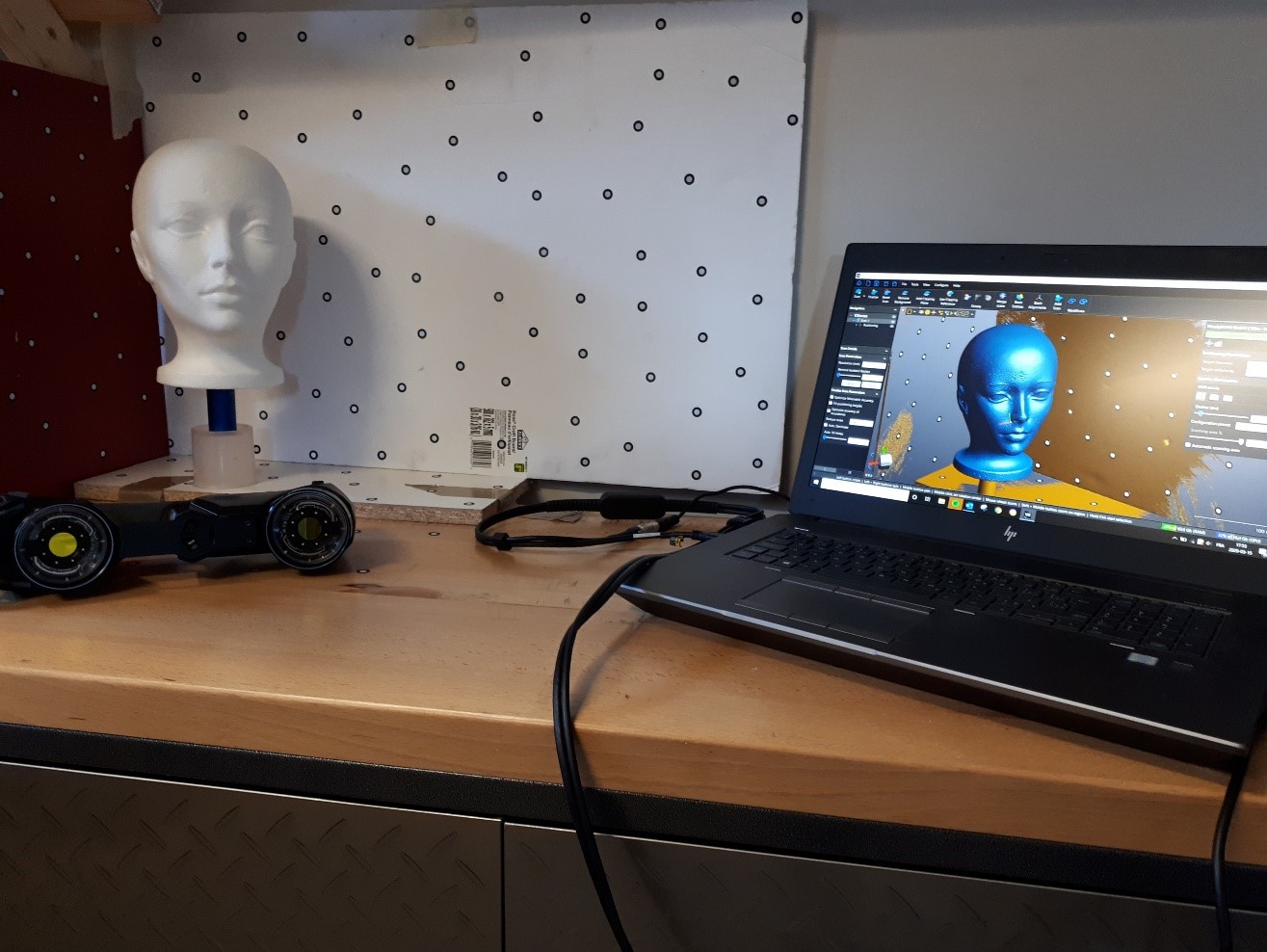

Another project under our belt! Recently, MR Industries in Acton Vale contracted us to do the complete reverse engineering of a shaft operating on a cardboard winding machine. It sounds very simple when you say it like that, but it's a very complex part! Indeed, its structure allows air circulation from one end of the machine to the other. It also feeds a pneumatic clutch system, which manages the variation in the speed of winding the carton. So it's quite a challenge to be able to scan all the surfaces of the part! And that's exactly the kind of challenge that the 3D PreciScan team LOVES to accomplish. See in the photos the evolution of the imagery of the part, from one stage to the next!

The original part to scan:

Image of the scanned axis:

Image of the Meshing/STL File:

Image of the 3D made in SolidWorks:

Image of the 2D made in SolidWorks:

Thank you to MR Industries for trusting us.

Since 1985, MR Industries has been working in the machining, metallization and welding of large parts, as well as in the reconditioning (retrofit) of machine tools. It uses its expertise in several sectors of activity: steel, aluminum smelter, forestry, paper mill, energy, chemical and mining industries.

_1677023041.png)