WIG HEAD

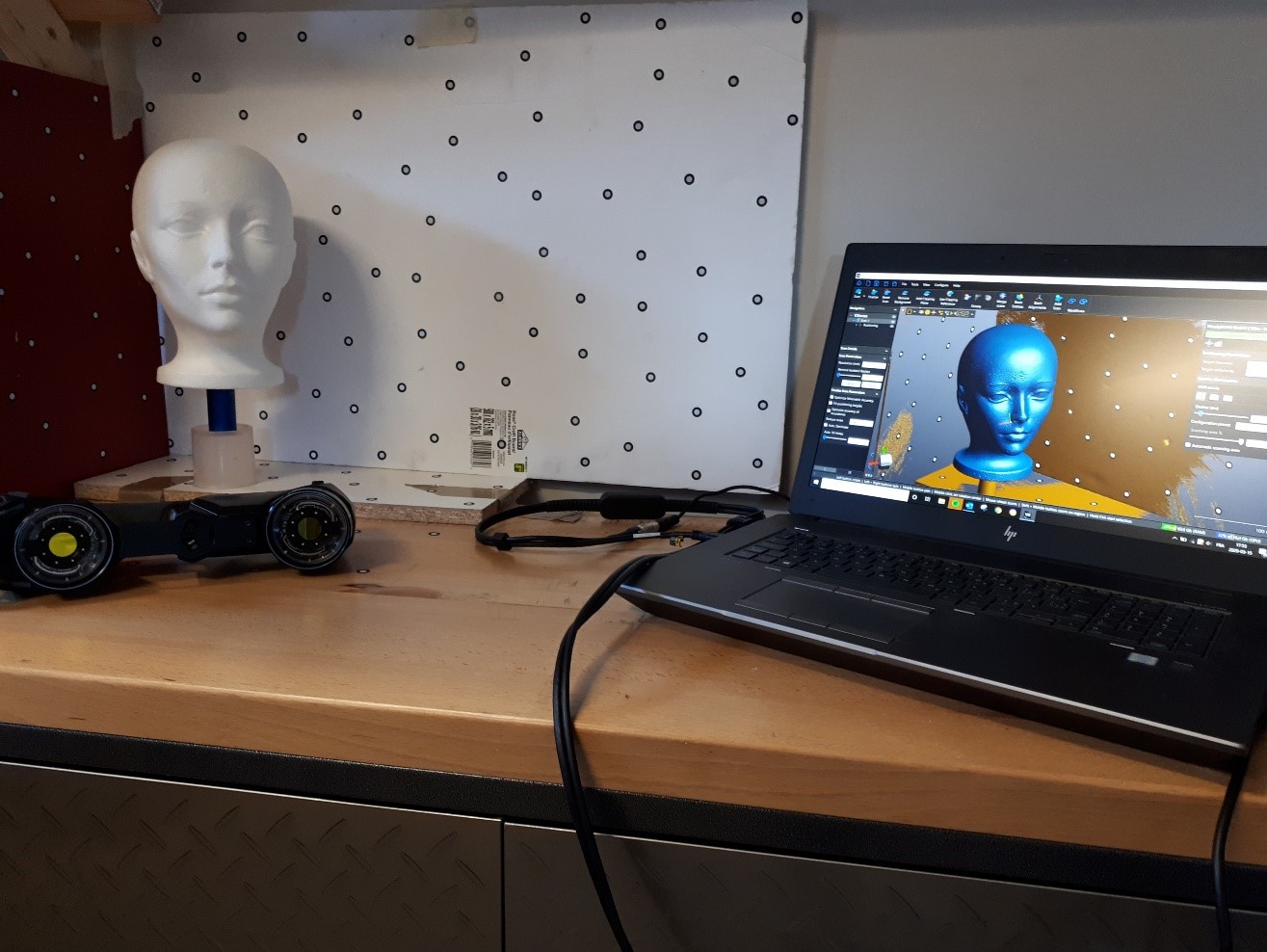

Les Moules Samco Inc. commissioned 3D PreciScan to reverse engineer a wig head whose mold to be replaced was more than 60 years old.

Result of the head scan:

Surface mesh of the head:

Result of the head in finite area:

Colorimetry Check Report:

We made a comparison by superposition between the scanned white head (reference) and the resurfaced head. Green areas represent areas that meet shape tolerances of +/-.02 in.

The goal was to deliver the 3D model from a polystyrene molded part. It was directly from the 3D model that Les Moules Samco was able to build a new mold to then produce other wig heads to deliver to its customer. This was a real challenge for 3D PreciScan, since the original part was made entirely in surface.

Les Moules Samco Inc. has been manufacturing industrial molds (non-ferrous metals, plastic, composite, wood and urethane) for 35 years.