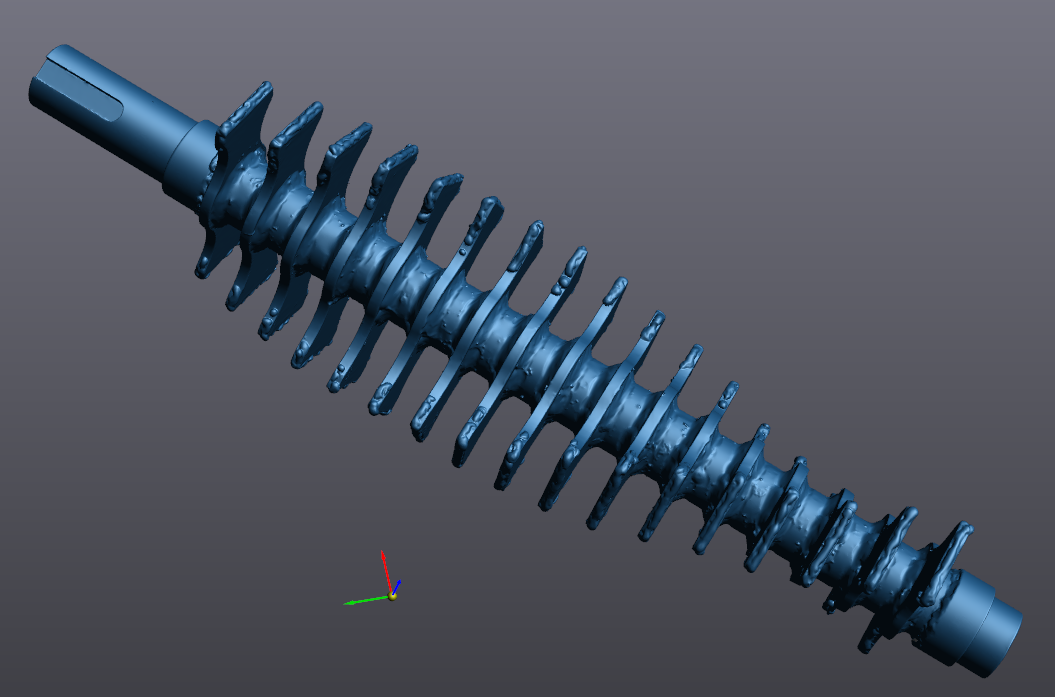

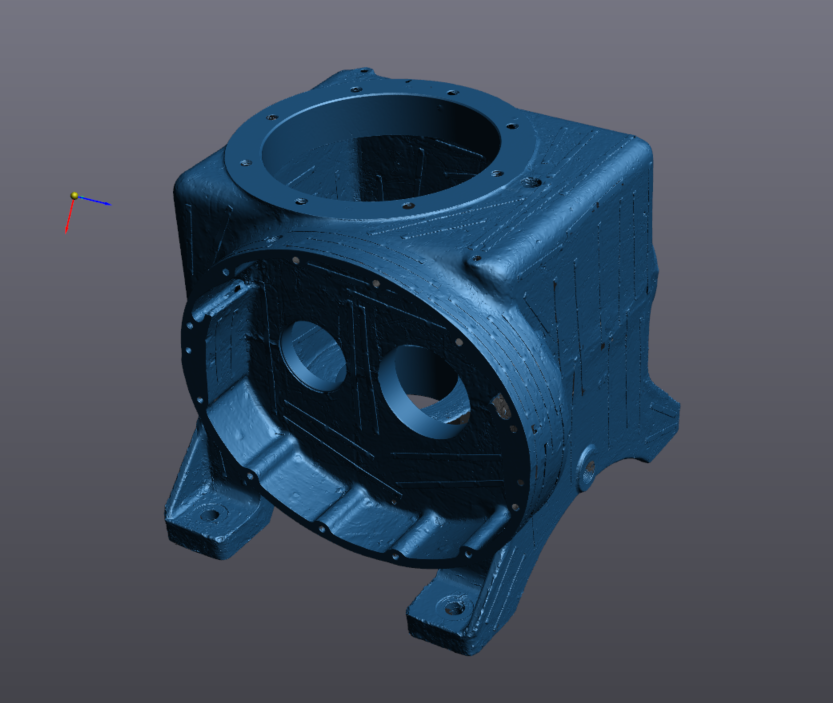

Here is an example of a COMPLETE reverse engineering achievement for our good customer GSR construction! The mission: to deliver a brand new shredder shaft, simply from the old part.

REVERSE ENGINEERING

WHAT IS REVERSE ENGINEERING?

The service : Like reconstruction, when the 3D of a part is not or is no longer available, we recreate the 3D model of the part from the intrinsic dimensions via the scan and we deliver a 3D file in STEP format. Reverse engineering also makes it possible to deliver 2D drawings with apparent dimensions so that the part can be manufactured by a welder, a foundry, etc. The 2D drawings are signed by an engineer.

Terms & Conditions : This service is for you, if you need 3D to repair an old machine that is still working and is no longer supported on the spare parts market, as well as, for industries that need to remake or replace a broken part. The difference with 3D reconstruction is that this service requires the supervision of an engineer. You have to understand what the part is for and how it works mechanically and to do that we need the material and the surface treatment.

It should be noted that this service is more complex, more time-consuming and requires more precision than the 3D reconstruction service. Our team works with specialized software, in our case, Geomagic Design X ($25k per License) and SolidWorks.

Service time : 4 to 6 weeks in general depending on the complexity of the part after performing the scan.