ALUMINUM Cover

3D PreciScan was entrusted by Yves, a private individual, for the reverse engineering of an aluminum cover.

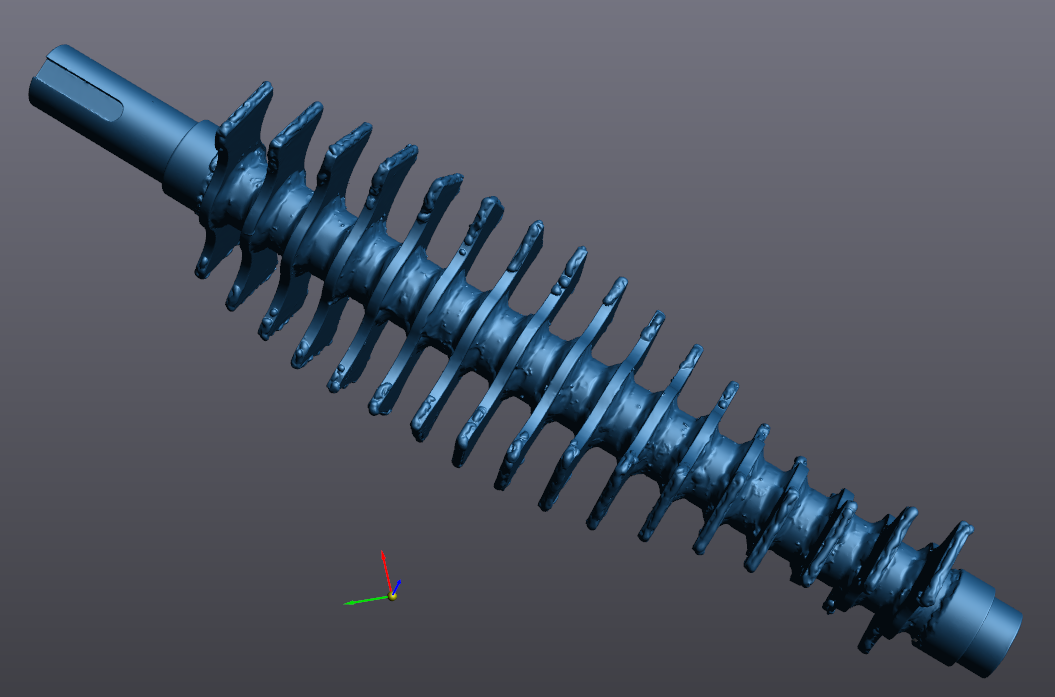

Aluminum cover to scan :

Scan of the inside of the cover:

Our client needed the cover remade in a simplified model in order to adapt it to a new application. 3D PreciScan scanned the part and performed reverse engineering on the cover by making the simplifications required and by transferring the precise interfaces needed.

Reverse engineering of the simplified cover:

Superimposed scan with the 3D scan of the simplified cover:

Blue: scan Grey: final part

Another superimposed image of the scan:

Orange: interior of the scanned cover Blue: outer contour (necessary part only and 3D scan of the simplified cover). After verification, we emailed the 3D version of the part to the client so they could import it directly into Mastercam (computer-aided manufacturing software) and prepare the machining program. All that, without the need for a 2D drawing! Much-appreciated time savings made possible by our 3D scanning services.

Final machined part:

Final part installed:

_1677023041.png)

_1677021317.jpg)