THERMOFORMED PLASTIC PART (AUTOMOTIVE INDUSTRY)

3D PreciScan received a request from EXO-S to inspect a thermoformed plastic part for the automotive industry. Having remade his mould, the client wanted to ensure the correct dimensional results of the part, as well as the influence of the removal of the plastic.

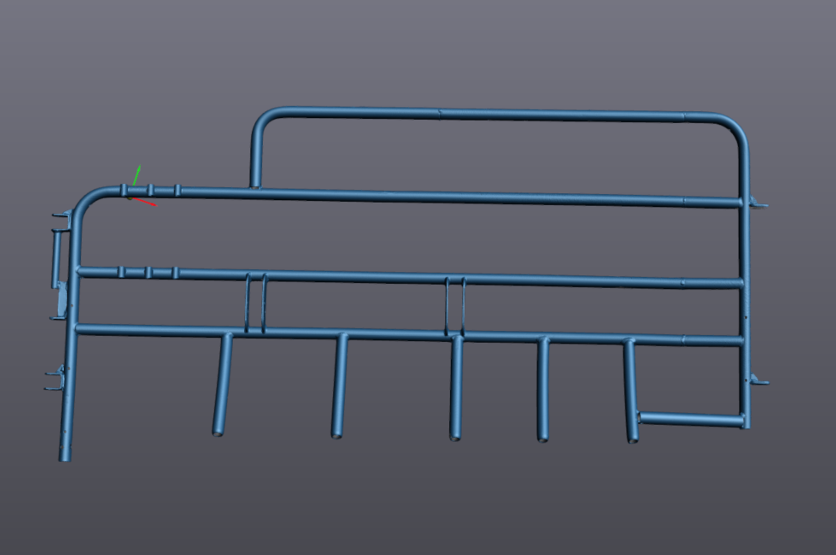

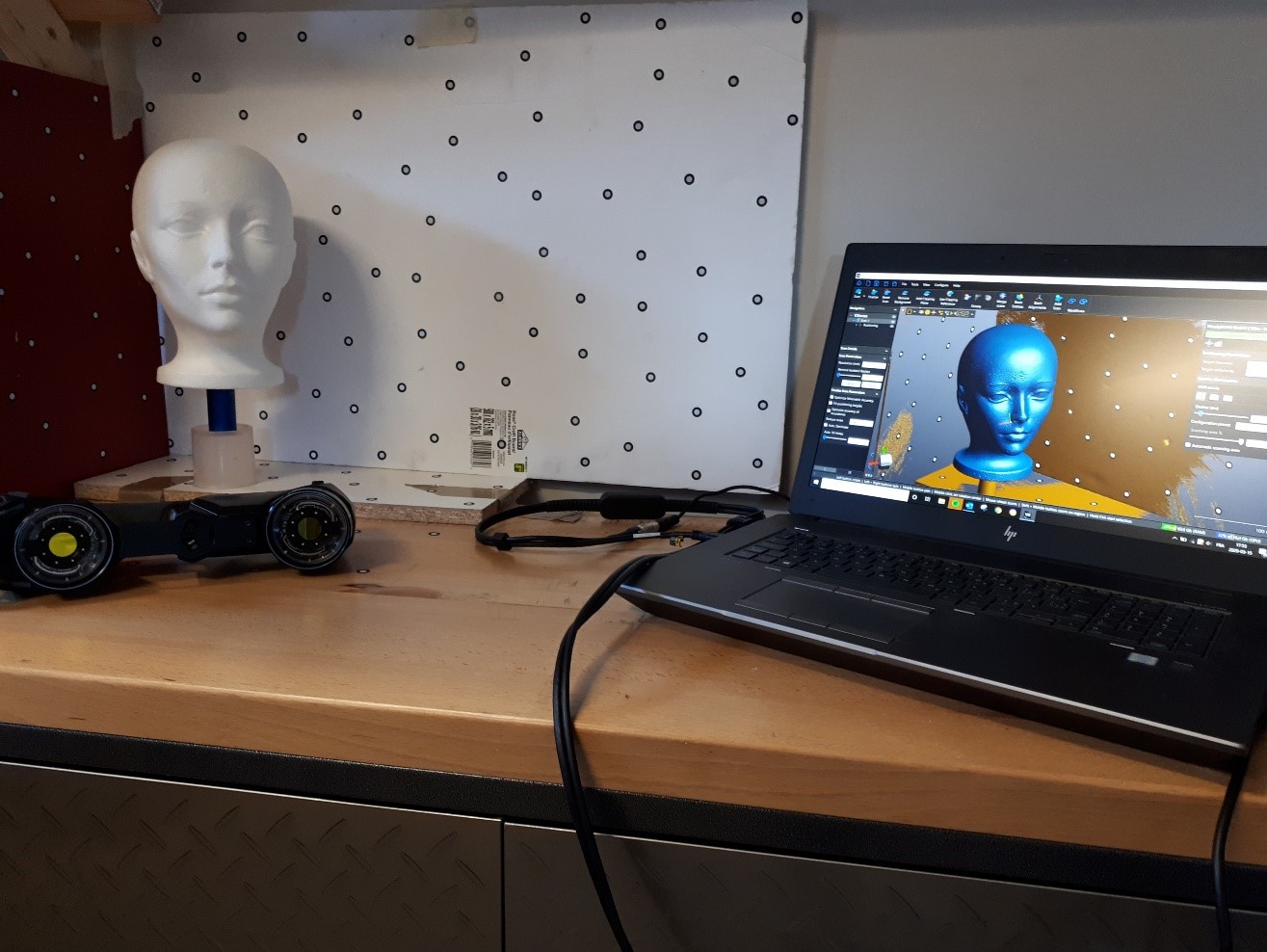

Original part to be scanned:

Original part, digitized:

This is because after a certain number of production runs, a mold ages, wears out and needs to be changed. Since this mold then produces parts that must be of high quality, the company EXO-S asked us to validate the first part produced by this mold. We provided a colorimetry control report following a shape tolerance scale of +/- 60 thousandths of an inch. In the image of the original scanned part, it can be seen that the black or pink areas of the part are outside this shape tolerance provided. This makes it very easy and quick for the customer to identify risk areas and make decisions about the actions to be taken to correct the situation.

EXO-S specializes in the design and manufacture of tooling for the production of plastic parts for specialized applications in the automotive sector and beyond.

_1677021317.jpg)