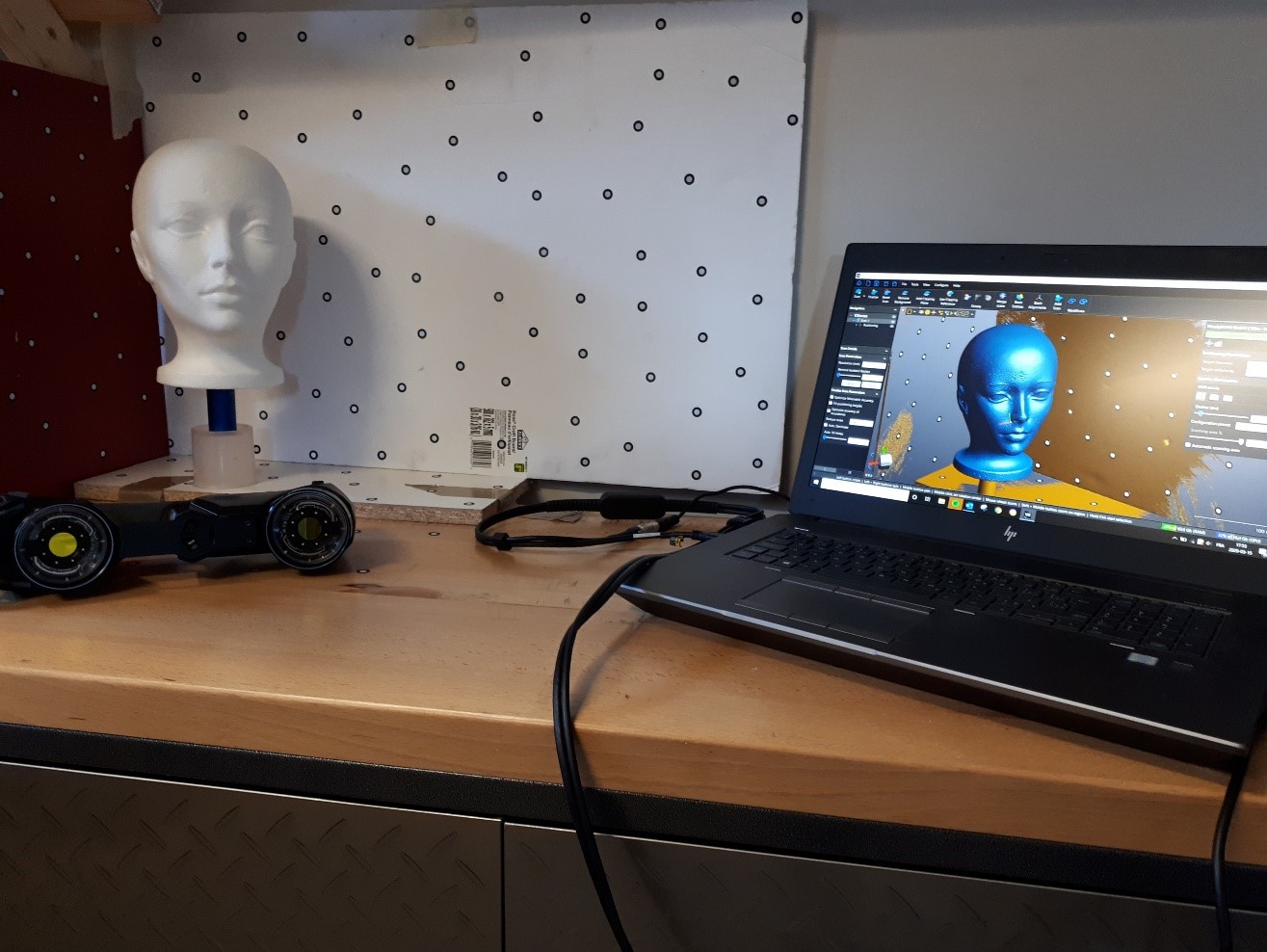

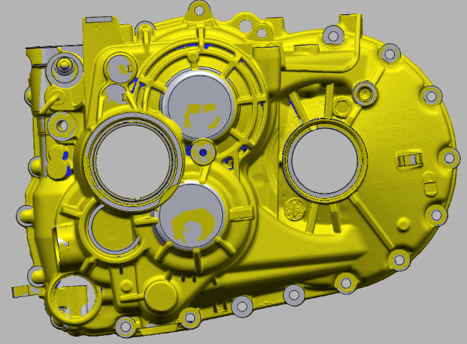

BARRIER

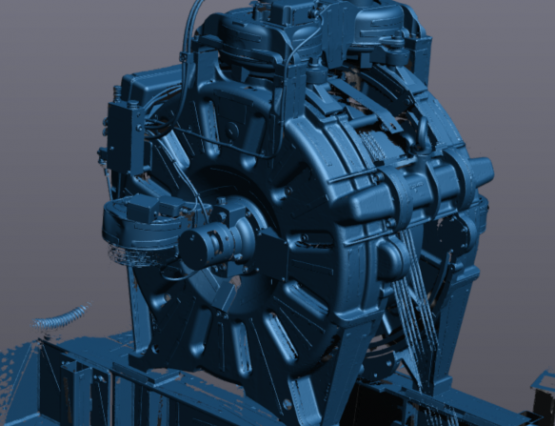

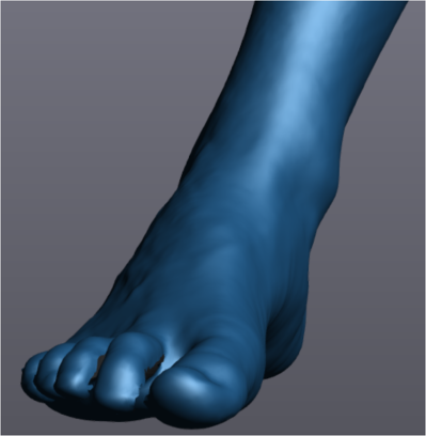

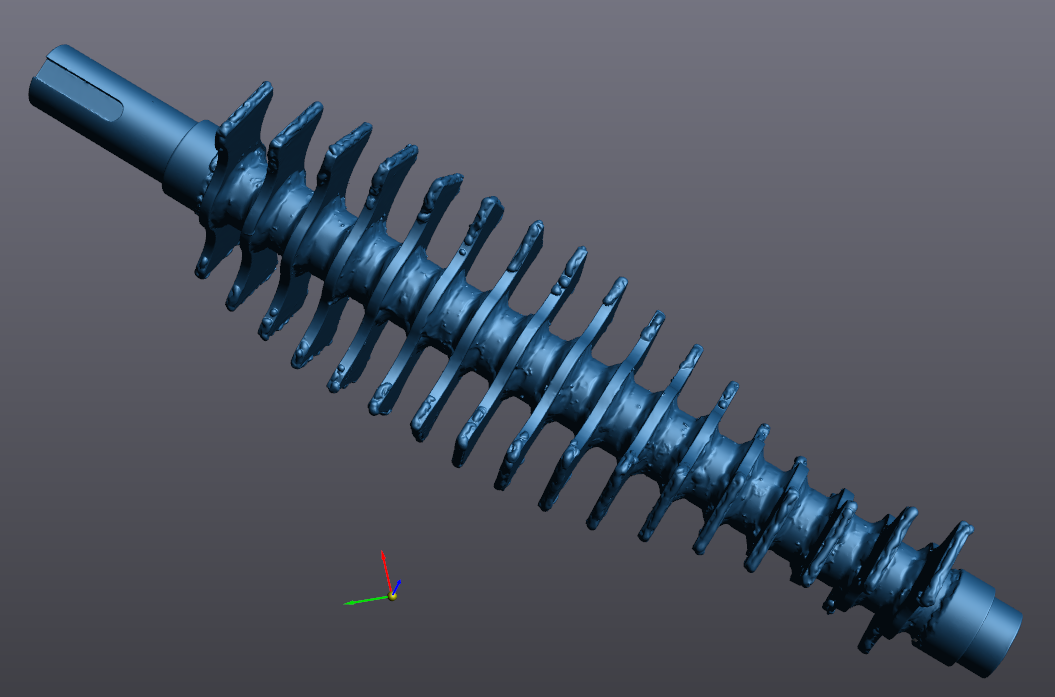

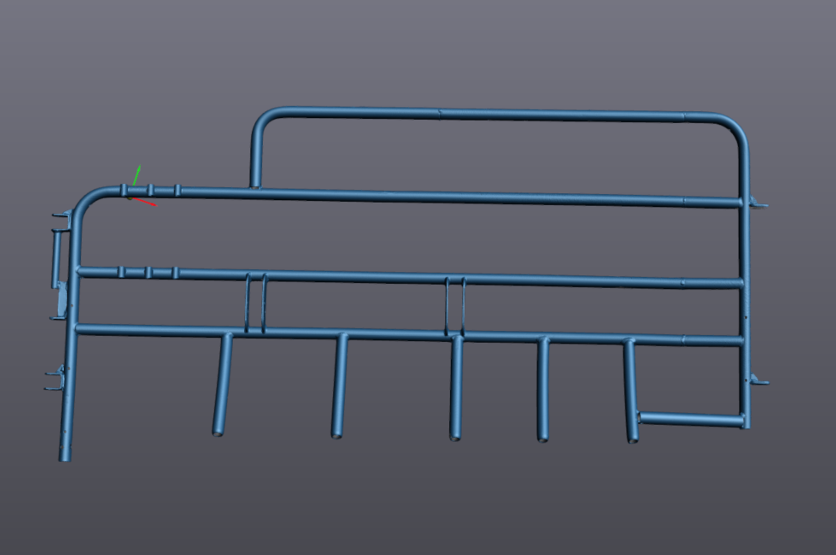

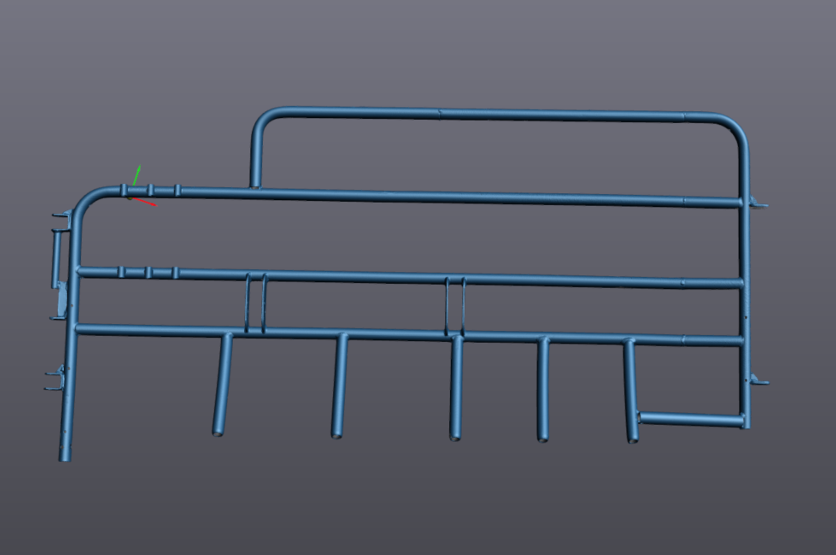

Earlier this year, GDL Equipment mandated us to completely reverse engineer a series of gates and gates for the pork industry. A great challenge that presented itself to us, once again! Here you will find an overview of the steps required to carry out such a project: 1. Scan the part, clean the scan and generate the meshing (STL file) 2. Align the STL file to prepare it for reverse engineering in SolidWorks 3. Create the 3D in SolidWorks based on the STL 4. Verify the 3D generated with the STL in PolyWorks Inspector to control the quality of the 3D 5. Realize the 2D 6. Verify the 2D for signature by the engineer who supervised the work throughout the process 7. Deliver to the customer. Always stimulating to support our customers in their innovative R&D needs! In the end, our scans will serve as the supplier's blueprints for the manufacture of the various parts in the series, which will then be distributed to farmers who raise pigs in Quebec! Thank you to GDL Equipment for trusting us with this great mandate! We leave you with these images which illustrate a glimpse of the evolution of the different steps within a reverse engineering process!

One of the parts to be scanned - A barrier:

Image of the scanned barrier:

Image of the mesh barrier (Meshing/STL file):

3D rendering using SolidWorks:

2D image taken in SolidWorks: